Industry Insights

Accelerate agricultural machinery design with Solid Edge

Agricultural machinery manufacturers face pressure to improve the speed and efficiency of their product design and

engineering processes so they can deliver new designs on time, and meet their customer’s expectations for reliability and low running costs.

Solid Edge® software from Siemens PLM Software enables manufacturers to respond rapidly to major trends that are impacting farming and agricultural machinery manufacturing including:

• Increasing demand from farmers for more flexible, multi-use machinery that enables them to respond to fluctuating grain and livestock prices

• Increasing demand for reliable, low cost equipment that minimizes capital expenditure and running costs

• Increased use of sensors and Geo-location to improve farming efficiency www.siemens.com/solid edge

• Government support for mechanization in developing countries

• Rising material and energy costs that threaten manufacturers’ profit margins

To respond to these trends and be successful in the competitive agricultural machinery market manufacturers can

improve their performance in these key processes:

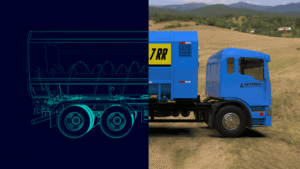

Communicate new designs to potential customers

Agricultural machinery manufacturers can substantially improve how they communicate designs to potential customers before the product is manufactured, and sales personnel can quickly convey the innovative features and value of their designs.

Solid Edge makes that possible by enabling you to create rich 3D product information, including high quality rendered images and animations. As a result, you’re able to clearly demonstrate your innovations through the use of the latest design and visualization technologies.

The Solid Edge advantage:

• Meet increasing demand for machinery with shorter product development times

• Support innovative machinery and equipment design with powerful, flexible 3D design tools

• Facilitate feasibility studies with rapid 3D modeling to assess new product designs and configurations

• Easily integrate standard and catalog parts from external suppliers into your designs

• Perform virtual testing of your designs to eliminate interference between moving parts, and minimize manufacturing issues

The Solid Edge advantage: continued

• Take advantage of Solid Edge Simulation analysis capabilities to optimize designs for high performance and durability while minimizing material costs

• Reduce end-user operating costs with efficient machine designs

• Demonstrate compliance with government and industry regulations with secure document control and electronic workflow management and signoffs

• Improve customer service by providing high quality, illustrated maintenance documents and maintaining accurate as-delivered BOMs

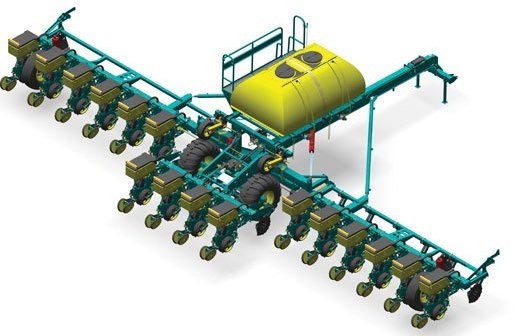

Perform feasibility studies

Assessing the feasibility of new products and sourcing components and sub assemblies from external suppliers is an important part of the design process for machinery manufacturers. For example, what changes will you need to make to fit a new pump design into your existing equipment? Solid Edge has unique capabilities to incorporate designs from external suppliers in a variety of computer-aided design (CAD) formats, and gives your designers the ability to edit these designs.

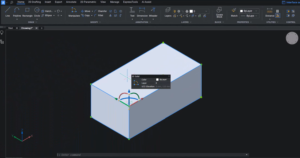

Speed 3D mechanical design

Designers and engineers are under pressure to work faster as well as produce accurate 3D part models, assemblies and 2D drawings. Siemens PLM Software provides a complete software portfolio to speed design and eliminate errors before manufacturing. This enables you to make design changes faster and deliver products sooner.

Configure standard products to meet customer needs

Sales and engineering staffs can configure standard products to meet customer needs while minimizing the need for one-off customized product development. Siemens PLM Software enables you to manage the product configuration throughout the sales cycle, including selecting the optimum configuration based on experience and standards. This reduces risk by enabling you to fulfil more orders with standard, predictable product configurations.

Integrate electrical wiring and components

There is a trend toward using more sensors and actuators in agricultural machinery,

so routing electrical wiring and housingfocuselectronic components is an important

part of the design process. Siemens PLM Software helps by enabling you to model electrical wiring, connections and

housings. You can calculate correct cable lengths and define accurate bills-of-

materials (BOMs) for electrical components.

Produce fabricated structures

Manufacturers need to develop a lot of fabricated steel content and engineers need to consider structural integrity and welding standards while minimizing material costs. Siemens PLM Software helps you accomplish this by providing tools for structural steel design and detailing, and you can simulate and test structures using embedded simulation capabilities. This enables you to optimize structures and minimize material and manufacturing costs.

Design sheet metal components

Manufacturers need to design safety guarding, housings, brackets and other sheet metal content in the context of the complete machine. Siemens PLM Software assists you by providing industry-leading sheet metal design and detailing solutions so engineers can produce accurate flat patterns and send the geometry directly to manufacturing. This enables you to streamline sheet metal design and manufacturing, reducing costs and speeding delivery.

Design for manufacturing

Improving the design to minimize manufacturing costs and understanding suitable tolerances and when to use machining or weldments is critical for manufacturers.

Key solution components

• Solid Edge for 3D part and assembly design using synchronous technology accelerates machinery design, speeds revisions and improves the re-use of proven components in new designs

• Solid Edge Simulation for digital validation of critical components reduces the need to create physical prototypes, lowers material and testing costs and improves reliability and durability

• Solid Edge Manufacturing for definition of accurate machining, fabrication and assembly processes improve overall manufacturing efficiency

• Solid Edge Design Management improves the overall efficiency of machinery design processes and projects, and ensures that accurate product data, specifications and requirements documents are easily accessible

Siemens PLM Software helps manufacturers overcome these challenges by providing standard geometry linked with available tooling, making design data easily accessible to manufacturing. Designs are optimized for production capabilities, and manufacturing errors are reduced.

Prebuild testing and prototyping

Typically, agricultural machinery designers have to wait until a machine is built to identify engineering problems. However, by creating 3D models of machinery and equipment, engineers can investigate different solutions and refine machine functions. Integrated simulation tools include static, kinematic, dynamic and fatigue analysis, and the end result is a significant drop in costs and time-to-delivery as engineers solve problems before manufacturing begins.

Manage quality assurance and compliance

Significant time and effort may be needed for quality assurance and to demonstrate compliance with government and industry regulations. Siemens PLM Software enables you to work efficiently in this area by providing the ability to manage regulatory requirements and documentation, create print files of designs to ensure released versions cannot be changed and implement electronic workflows for controlled, consistent process completion. As a result, you have reliable audit results and a reduced risk of litigation.

Visual design and project management

Manufacturers need to retrieve data quickly, optimize resources and manage engineering changes efficiently. Siemens PLM Software helps by providing visual design management tools that include pre-configured workflow capabilities, enabling your team to access and track design projects and engineering change information.

Mobile access to your design projects

Engineers need access to accurate design, installation and maintenance information while working on the shop floor and at remote locations. Siemens PLM Software provides mobile viewing of 2D drawings and 3D CAD models, enabling you to understand service procedures using 3D interactive product information.

Realizing significant benefits

Agricultural machinery manufacturers report that they are achieving significant benefits using Solid Edge. Some examples from published case studies include:

• Successfully competing with larger manufacturers while using fewer resources

• Reducing development time for new machinery by 60 percent

• Completing design changes 75 percent faster

• Minimizing errors in manufacturing and service

• Decreasing manufacturing lead time by 30 percent

• Demonstrating compliance with government regulations