The latest release of BricsCAD Mechanical V24.2 introduces enhanced features intended to make your assembly manual creation and inspection workflows more efficient. With the integration of Design for Manufacture and Assembly (DFMA) optimization and validation workflows, users can streamline the assembly process, reduce manufacturing complexities, and identify cost-effective design changes early on.

Let’s explore the critical aspects of this improved Assembly Optimization Workflow and how manufacturing professionals can leverage the new features in BricsCAD Mechanical V24.2.

Key Enhancements to Assembly Sequence Development

In BricsCAD Mechanical V24.2, you can develop a drafting sequence using the BMSEQUENCE command. This command facilitates the creation of build steps, mirroring the sequence in which components would be assembled in real-world scenarios.

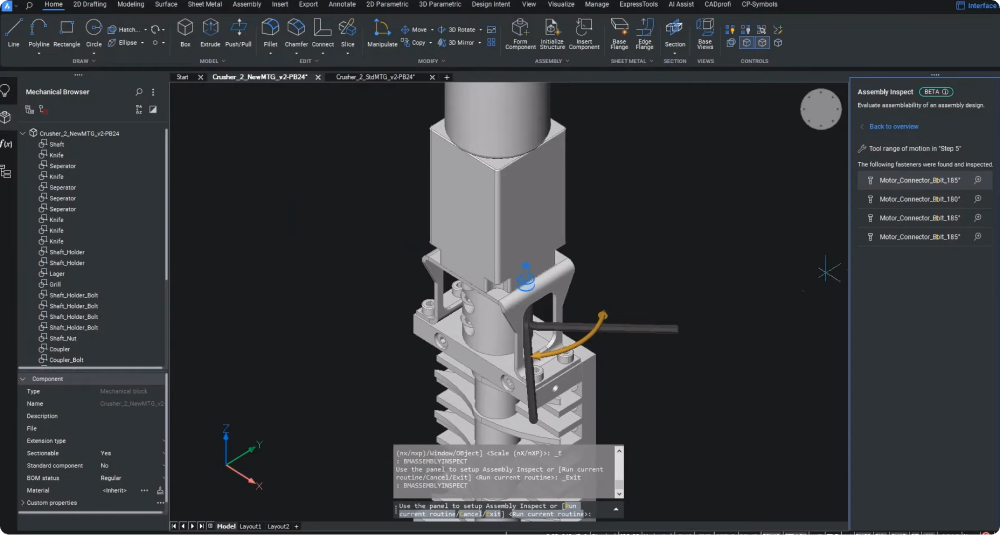

Assembly Inspection Tool

BricsCAD Mechanical V24.2 extends the capabilities of the BMASSEMBLYINSPECT command to evaluate assembly parameters more effectively. With this command, users can delve into the inspection phase of the workflow. The command focuses on two significant aspects: tool usage and gravitational stability.

- Tool Usage: This evaluation tests whether tools have a sufficient range of motion in reference to their position within the assembly at a specific sequence step.

- Gravitational Stability: This new feature checks whether a component is gravitationally stable before fixing the fastener. If stable, the assembly technician can use both hands to pick a fastener and a tool, increasing ergonomic efficiency.

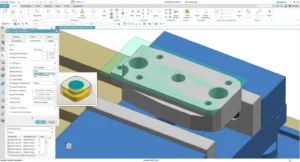

Adding Tools and Fasteners

BricsCAD Mechanical V24.2’s assembly inspect settings allow users to add the tools required for evaluating the assembly, enabling the use of either the software’s standard toolkit or specialized tooling. The Routine Editor Dialog facilitates mapping these tools to their corresponding fasteners or fittings.

Evaluating Test Results

When you’ve defined the assembly sequence, all the steps appear with options to inspect individual parts and assign testing criteria. This command also runs the inspection tests, providing results within each step and for each testing option, giving an overall result based on individual criteria.

The communication of test results makes it clear where the assembly process needs troubleshooting. For example, if tool usage is restricted at a particular assembly step, it could signal the need for a design change to allow greater tool movement. Similarly, issues with gravitational stability can inform the need to adjust the assembly’s orientation at specific steps.

BricsCAD Mechanical V24.2 responds to these inspection results with straightforward actions. By making design changes, such as adding a hole on the side of the mounting bracket, the software demonstrates how a tool’s range of travel can be improved significantly, leading to more effective assembly processes.

To sum up, BricsCAD Mechanical V24.2 enhances manufacturing assembly workflows with its assembly inspection toolkit. By continually innovating features like the gravitational stability criteria and providing an updated feature dialogue for smoother workflows, BricsCAD fosters optimal, error-free assembly processes to stay ahead in the dynamic manufacturing and assembly world.